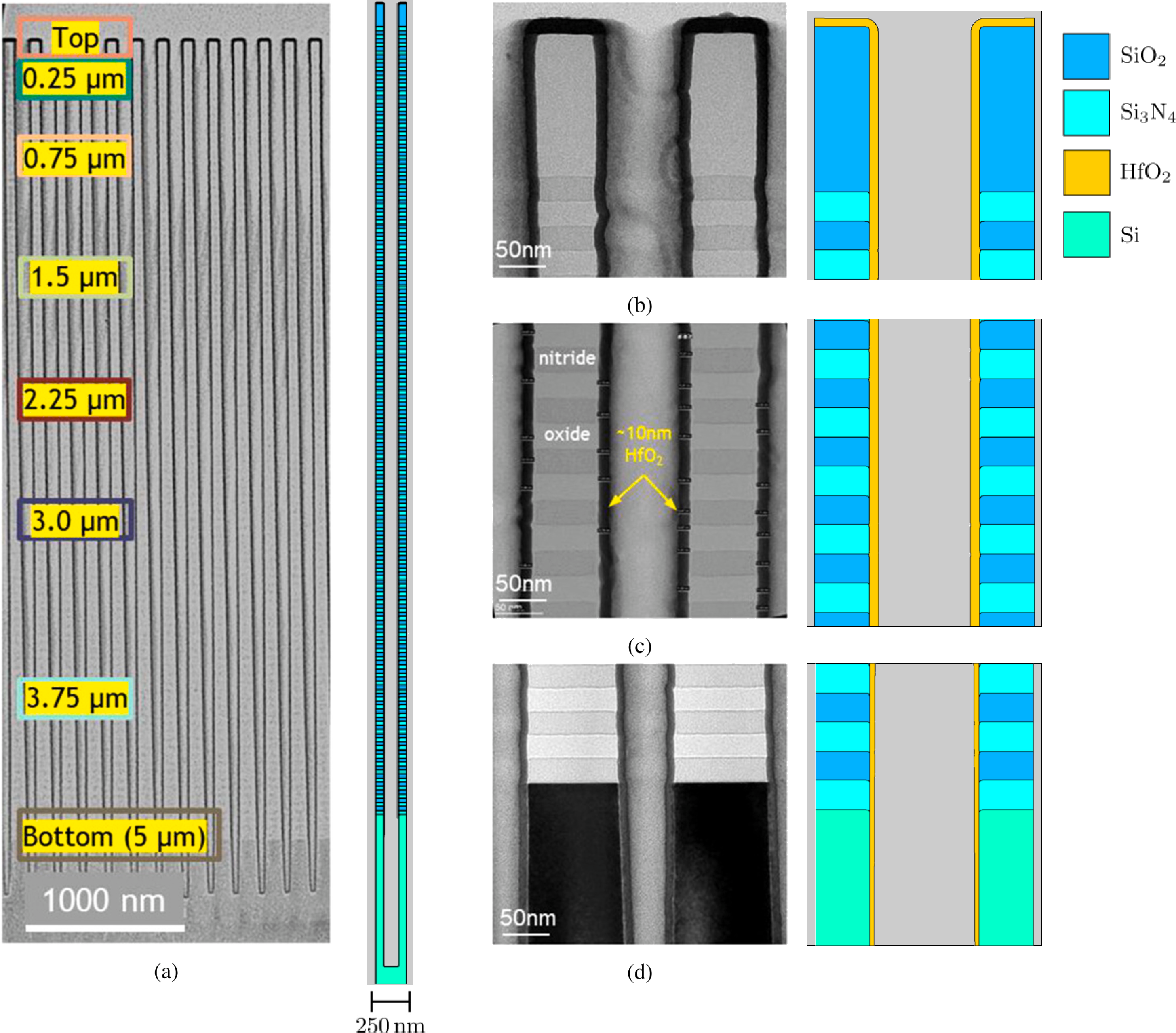

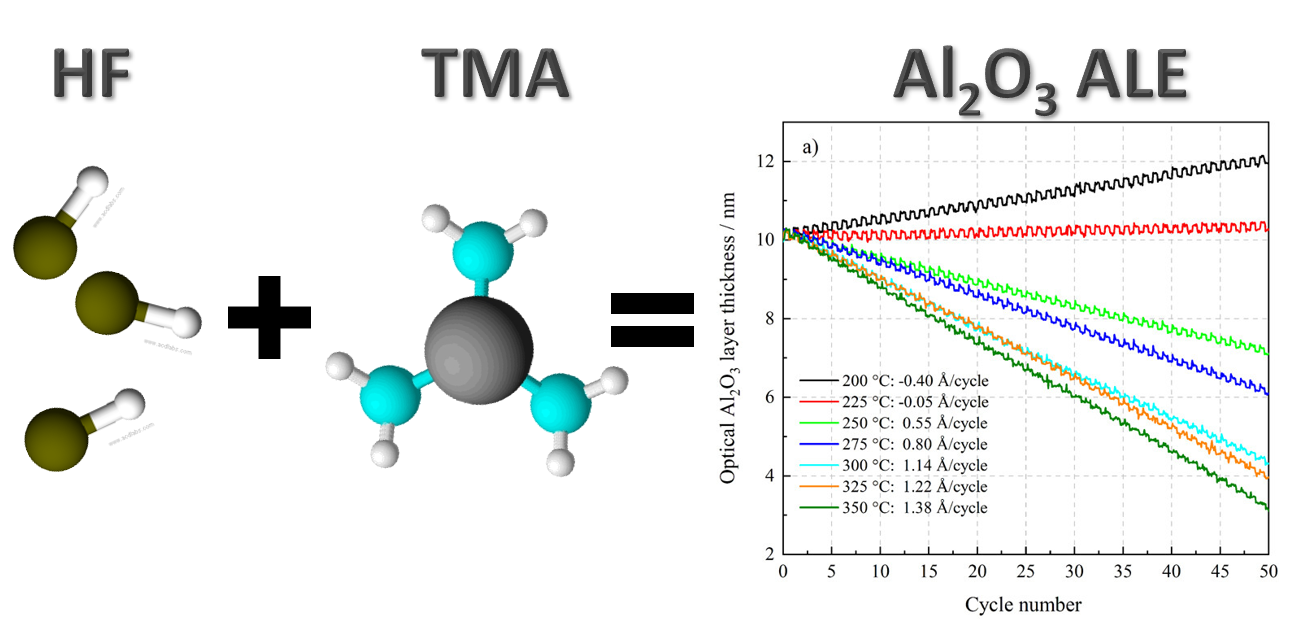

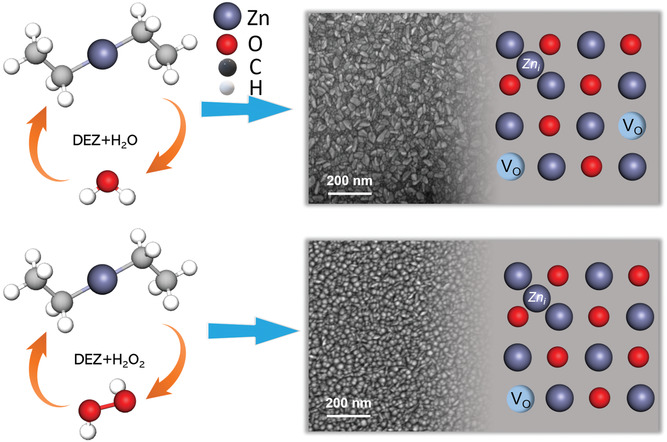

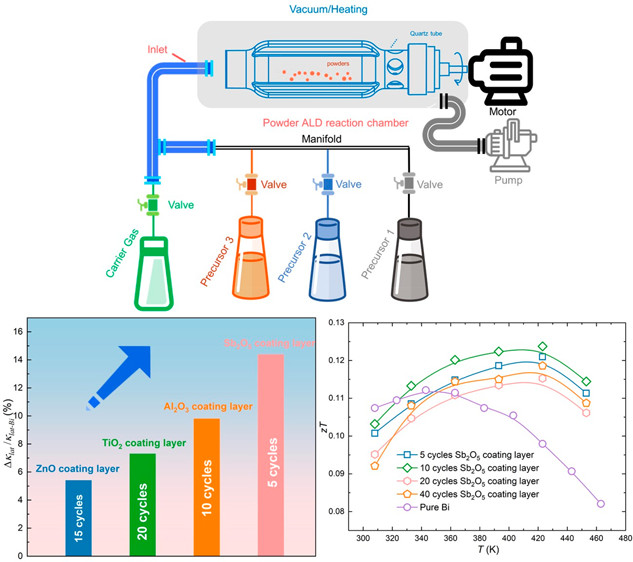

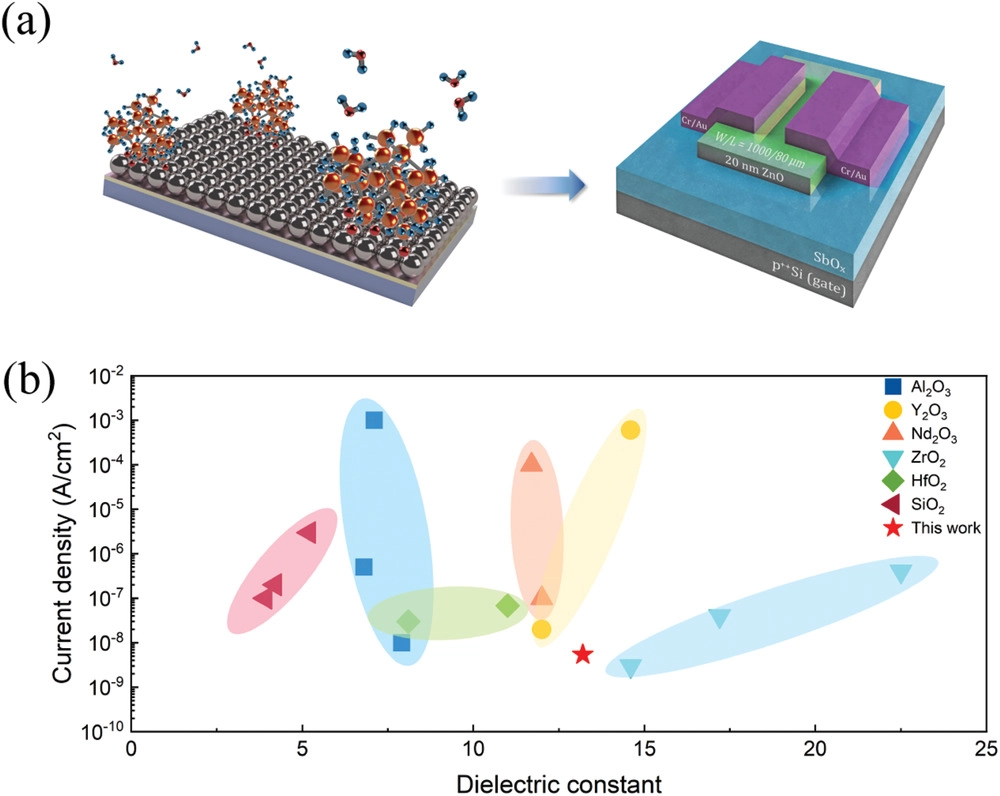

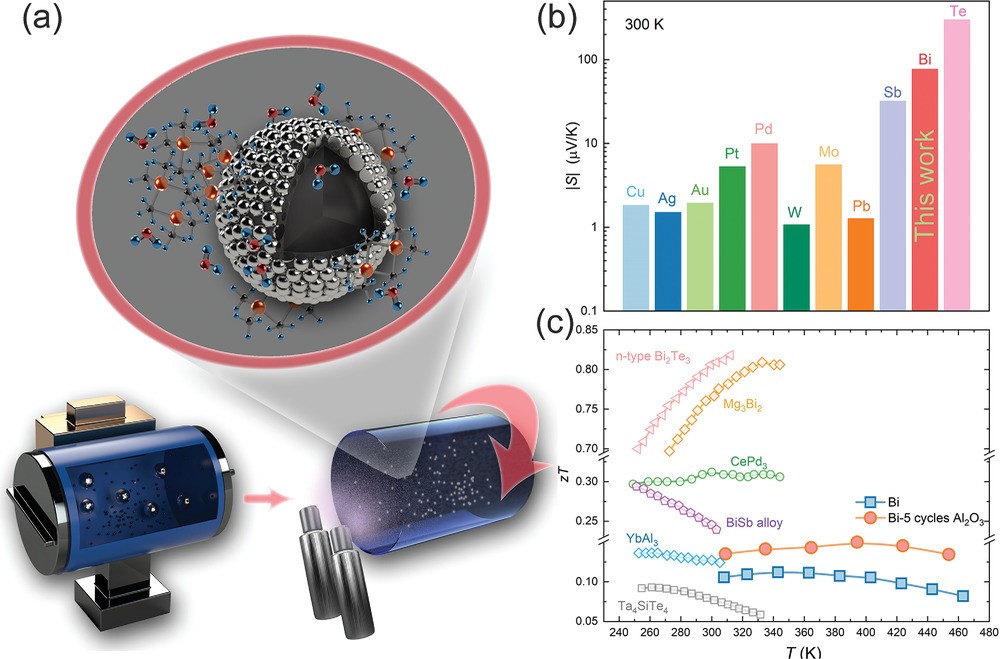

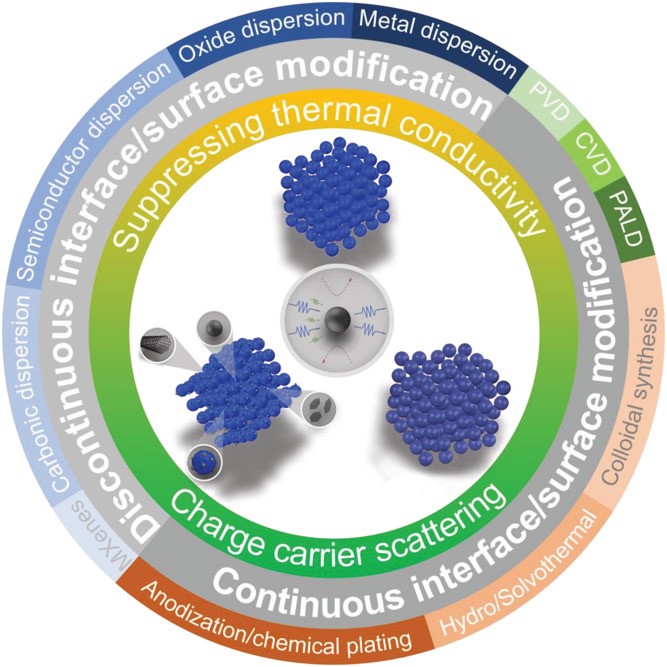

In thermoelectric materials, phase boundaries are crucial for carrier/phonon transport. Manipulation of carrier and phonon scatterings by introducing continuous interface modification has been shown to improve thermoelectric performance. In this paper, a strategy of interface modification based on powder atomic layer deposition (PALD) is introduced to accurately control and modify the phase boundary of pure bismuth. Ultrathin layers of Al2O3, TiO2, and ZnO are deposited on Bi powder by typically 1–20 cycles. All of the oxide layers significantly alter the microstructure and suppressed grain growth. These hierarchical interface modifications aid in the formation of an energy barrier by the oxide layer, resulting in a substantial increase in the Seebeck coefficient that is superior to that of most pure polycrystalline metals. Conversely, taking advantage of the strong electron and phonon scattering, an exceptionally large decrease in thermal conductivity is obtained. A maximum figure of merit, zT, of 0.15 at 393 K and an average zT of 0.14 at 300–453 K were achieved in 5 cycles of Al2O3-coated Bi. The ALD-based approach, as a practical interfacial modification technique, can be easily applied to other thermoelectric materials, which can contribute to the development of high-performance thermoelectric materials of great significance.